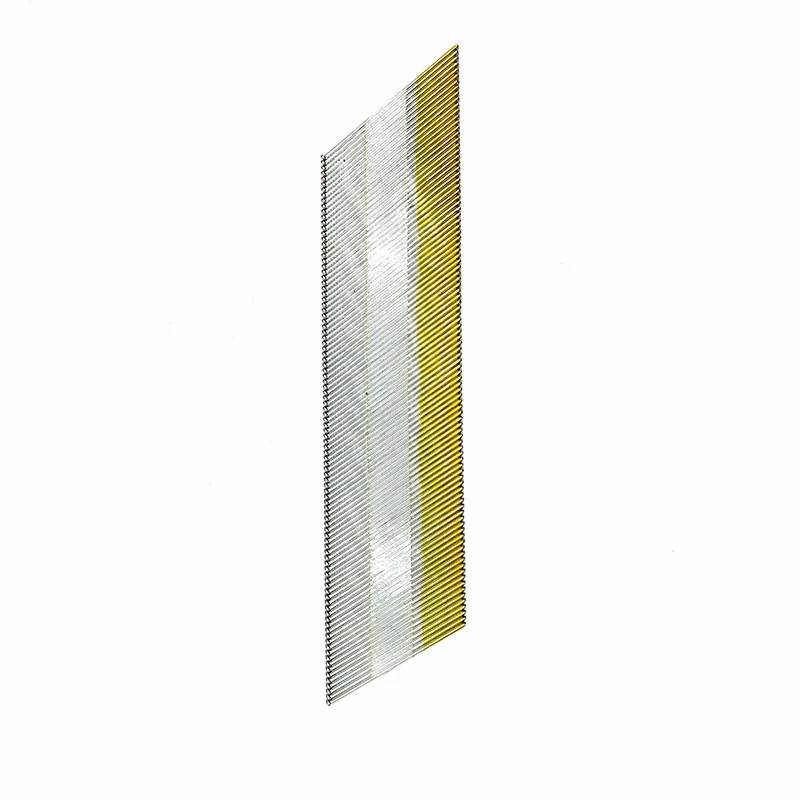

Stainless steel framing nails typically perform very well in terms of resistance to bending or buckling due to their inherent properties and characteristics. Here’s how they perform:

- Material Strength: Stainless steel is known for its high strength and rigidity, which makes it less prone to bending or buckling under load compared to other materials like carbon steel. This strength allows stainless steel framing nails to maintain their structural integrity even when subjected to high stress or pressure.

- Corrosion Resistance: Stainless steel is highly resistant to corrosion, which helps prevent degradation of the nail’s surface over time. Unlike carbon steel nails, which can weaken and corrode when exposed to moisture or harsh environments, stainless steel nails maintain their strength and resistance to bending or buckling even in corrosive conditions.

- Ductility: While stainless steel is strong and rigid, it also possesses a degree of ductility, allowing it to deform slightly without fracturing under extreme loads. This ductility helps stainless steel framing nails absorb and distribute stress more effectively, stainless steel framing nails reducing the risk of sudden failure or buckling.

- Consistent Quality: Stainless steel framing nails are manufactured to high quality standards, ensuring uniformity in size, shape, and metallurgical properties. This consistency contributes to reliable performance and resistance to bending or buckling across a wide range of applications and environmental conditions.

- Application Versatility: Stainless steel framing nails are suitable for various framing and construction applications, including heavy-duty framing, decking, fencing, and sheathing. Their versatility allows them to withstand different types of loads and stresses without bending or buckling, providing reliable fastening solutions for diverse projects.

Overall, stainless steel framing nails offer excellent resistance to bending or buckling due to their high strength, corrosion resistance, ductility, consistent quality, and application versatility. These properties make them a preferred choice for construction professionals seeking durable and reliable fastening solutions in demanding environments.

Comments